We offer revolution of industrial engineering

Contact Number

+(86)189-1838-3906

E-mail

info@mechvis.co

Contact Address

No.8 Yanggang Avenue Quanjiao, Anhui, China

Product List

9-Layer Co-Extrusion Blown Film Machine

The 9-Layer Co-Extrusion Blown Film Machine is a high-performance solution for producing premium films, widely used in food packaging, medical materials, and high-barrier functional films. Adopting bottom-blown technology, it ensures excellent film thickness uniformity, high transparency, and superior mechanical and barrier properties.

Main Components:

1.Extrusion System: 9 high-precision extruders supporting multiple raw materials.

2.Die Head System: High-precision 9-layer die head ensuring consistent layer thickness.

3.Cooling System: Combination of bottom air cooling and internal/external air rings for stable cooling performance.

4.Haul-off System: Multi-stage haul-off for flat and stable film output.

5.Winding System: Fully automatic dual-station winder for non-stop roll change.

Main Components:

1.Extrusion System: 9 high-precision extruders supporting multiple raw materials.

2.Die Head System: High-precision 9-layer die head ensuring consistent layer thickness.

3.Cooling System: Combination of bottom air cooling and internal/external air rings for stable cooling performance.

4.Haul-off System: Multi-stage haul-off for flat and stable film output.

5.Winding System: Fully automatic dual-station winder for non-stop roll change.

Eight-Layer Co-Extrusion Film Blowing Machine

This machine uses advanced eight-layer co-extrusion technology to produce high-performance films for food, industrial, and agricultural packaging. It supports functions such as high barrier, anti-fog, and puncture resistance, boosting product value. Equipped with an intelligent PLC control system, it offers automated operation, real-time monitoring, and stable, efficient mass production.

Main Components

1.Eight high-efficiency extruders (customizable screw designs)

2.Multi-layer co-extrusion die head (uniform layer distribution)

3.Upward blowing tower with stable air ring

4.High-efficiency cooling system

5.Haul-off and nip roller unit (ensures film flatness)

6.Automatic winder (constant tension & roll change)

7.PLC + touch screen control system

Main Components

1.Eight high-efficiency extruders (customizable screw designs)

2.Multi-layer co-extrusion die head (uniform layer distribution)

3.Upward blowing tower with stable air ring

4.High-efficiency cooling system

5.Haul-off and nip roller unit (ensures film flatness)

6.Automatic winder (constant tension & roll change)

7.PLC + touch screen control system

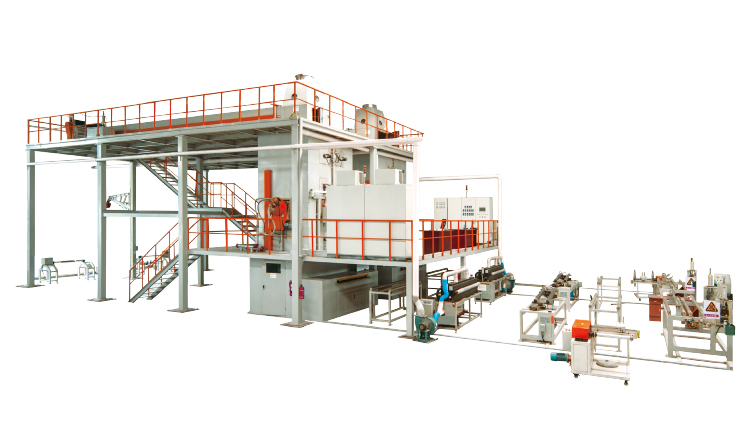

PP/EVA/EVOH/PS/PE Multi-layer Co-extrusion Barrier Production Line

In response to the increasingly stringent demands of the market, our company has developed advanced five-layer symmetrical and seven-layer asymmetrical distribution technologies, enabling the equipment to produce products with superior barrier performance.

The PP/EVA/EVOH/EVA/PP five-layer or seven-layer co-extruded composite high-barrier fresh-keeping packaging sheet offers excellent gas and moisture barrier properties, making it an outstanding plastic packaging material for gas barrier applications. It is mainly used for jelly packaging, premium meat products, ready-to-eat rice meals, as well as pharmaceutical and cosmetic packaging.

Double Column Double Station Hydraulic Screen Changer

The non-mechanical seal design ensures no material leakage under high-pressure and high-temperature conditions, effectively reducing screen-changing resistance and lowering the operating pressure of the hydraulic system.

High-quality alloy steel with nitriding treatment significantly extends the service life of the product.

The integrated engineering oil cylinder offers longer durability.

The alternating operation mode ensures continuous and stable material flow during the screen change, as well as repeatable process parameters.

The rheology-optimized breaker plate effectively reduces fluid shear during extrusion.

Equipped with a stroke position sensor, the screen change process is more precise and controllable.

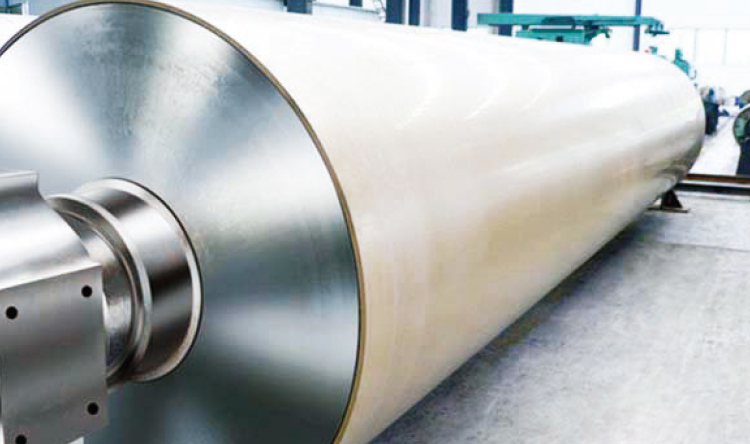

Rubber-Coated Roller

The rubber roller surface can be coated with materials such as EPDM, Hypalon, Nitrile Rubber, Silicone Rubber, and Polyurethane, offering oil and solvent resistance as required by different operating conditions. Its elasticity, wear resistance, and impact resistance directly affect quality and service life.

For high-temperature applications, a spiral cooling channel design with large water flow ensures uniform and controllable surface temperature. Precision grinding and strict static/dynamic balancing guarantee stable, high-speed operation, even on biaxially oriented film production lines.

PBAT Eco-friendly Sheet Production Line

Mechvis has developed the PBAT sheet production line for manufacturing multi-layer composite eco-friendly sheets, mainly used for thermoforming various food containers and packaging, such as trays, noodle bowls, lunch boxes, cake boxes, and fruit plates. This equipment efficiently utilizes a proportion of calcium carbonate (stone powder) to reduce raw material costs while enhancing the sheet’s biodegradability, maintaining excellent overall physical properties, and ensuring good subsequent processing performance.

XPE and IXPE Cross-linked Polyethylene Foam Sheet Production Line

XPE foam is a closed-cell material offering excellent thermal insulation, noise reduction, waterproofing, and chemical and heat resistance. Its roll form and good adhesion make it ideal for HVAC systems, piping, containers, roofing, luggage linings, electronics packaging, sports shoes, automotive insulation, and more.

IXPE foam features a smoother, denser surface with finer, uniform cells and superior physical properties. It is widely used in construction, piping, automotive, packaging, sports, and recreational industries.

Mechvis’s IXPE production lines include extrusion and pelletizing, sheet extrusion, and foam production, providing high-efficiency, reliable solutions.

PET/PLA/CPLA Eco-friendly Sheet Production Line

The twin-screw, no-drying, vented PET/PLA sheet production line features low energy consumption, a simple process, and easy equipment operation and maintenance. Its unique screw configuration effectively reduces the viscosity drop of PET/PLA resin. Symmetrical thin-wall rollers improve cooling efficiency while enhancing output and sheet quality. Multi-component feeding systems allow precise control of virgin material, regrind, and color masterbatch ratios. The produced sheets are suitable for thermoforming, printing, and packaging applications.

Upward Seven-Layer Co-Extrusion Blown Film Machine

Designed for producing high-barrier, high-strength films for food, pharmaceutical, industrial, and agricultural packaging. Features an automatic thickness measurement and closed-loop control system for uniform film quality, along with an intelligent PLC system for fully automated, energy-efficient, and stable operation.

Main Components

1.Seven high-efficiency extruders

2.Upward blowing tower with stable air ring

3.Automatic thickness measurement & control

4.High-efficiency cooling system

5.Haul-off & nip roller unit

6.Automatic winder

7.PLC touch screen control.

Main Components

1.Seven high-efficiency extruders

2.Upward blowing tower with stable air ring

3.Automatic thickness measurement & control

4.High-efficiency cooling system

5.Haul-off & nip roller unit

6.Automatic winder

7.PLC touch screen control.